About Us

Protecting Retail Value Through Intelligent Innovation

Founded in 2002, Sunshine Protecting Limited began as a specialist in manufacturing core frequency components for the EAS (Electronic Article Surveillance) industry. Over two decades, we have evolved into a vertically integrated leader, mastering every stage from precision component production to injection molding, OEM/ODM services, and full-system assembly. Since 2024, we also pioneer smart loss prevention solutions that seamlessly integrate RFID and EAS technologies – a testament to our relentless drive to innovate in response to modern retail challenges.

A brief history of Sunpro

Sunshine Protecting Limited (“SunPro”) is established

SunPro was established in Hangzhou in 2002. The company specializes in manufacturing frequency components used in EAS (Electronic Article Surveillance) tags.

First Manual Winding Equipment & Strategic Partnership

The first manual coil winding machines were introduced, and a strategic cooperation agreement was signed with the leading EAS company in Hangzhou city.

Diversified Coil Development for Various Frequencies

In addition to standard 8.2MHz and 58KHz products, SunPro develops and manufactures coils for various EAS applications, including 66KHz, 1.81MHz, 3.25MHz, 4.75MHz, and other customized frequencies.

Rapid Workforce Expansion Amid Growing EAS Demand

In 2007, as EAS technology and industry development accelerated, SunPro expanded its workforce to about 500 employees to meet rapidly increasing product demand.

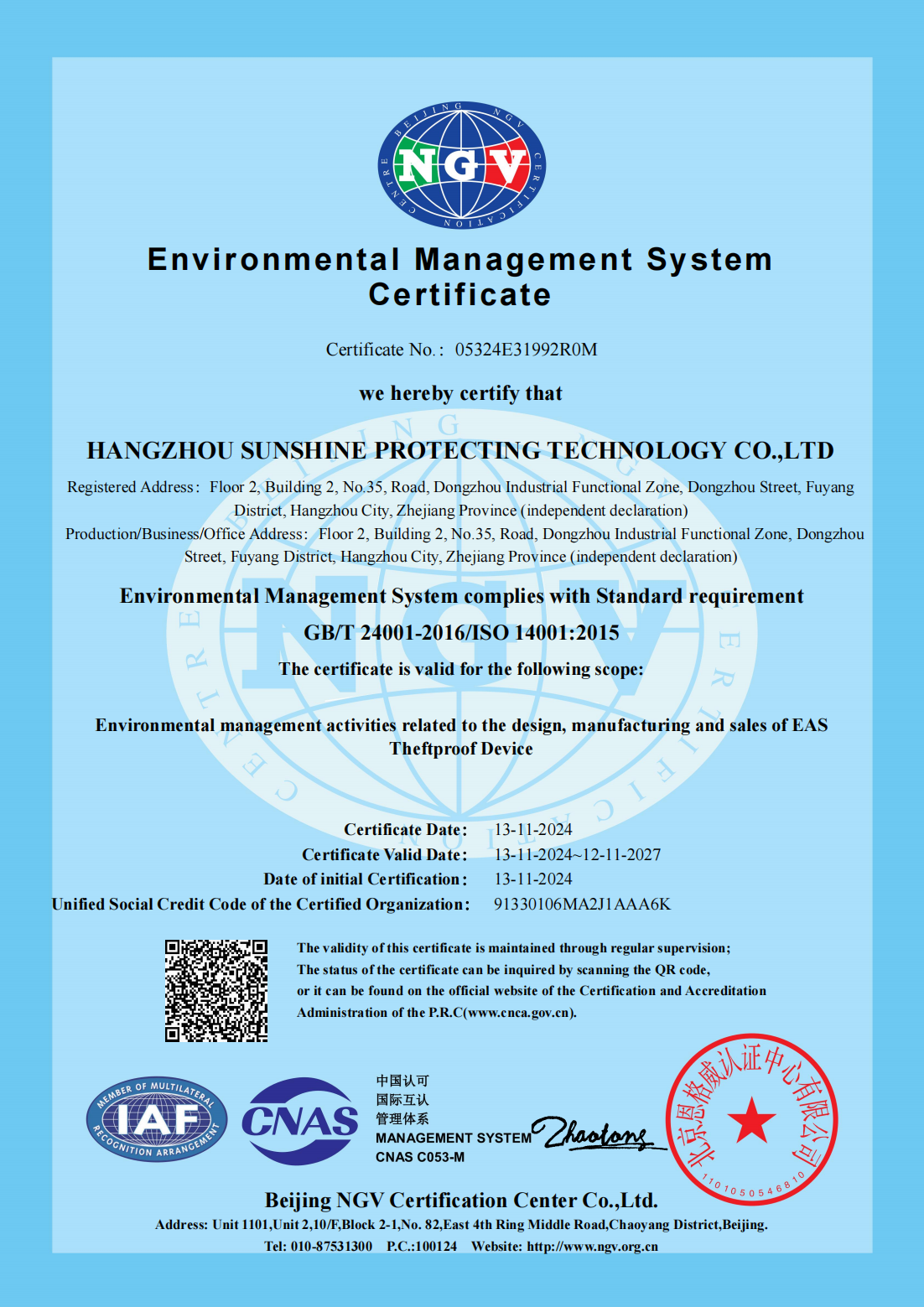

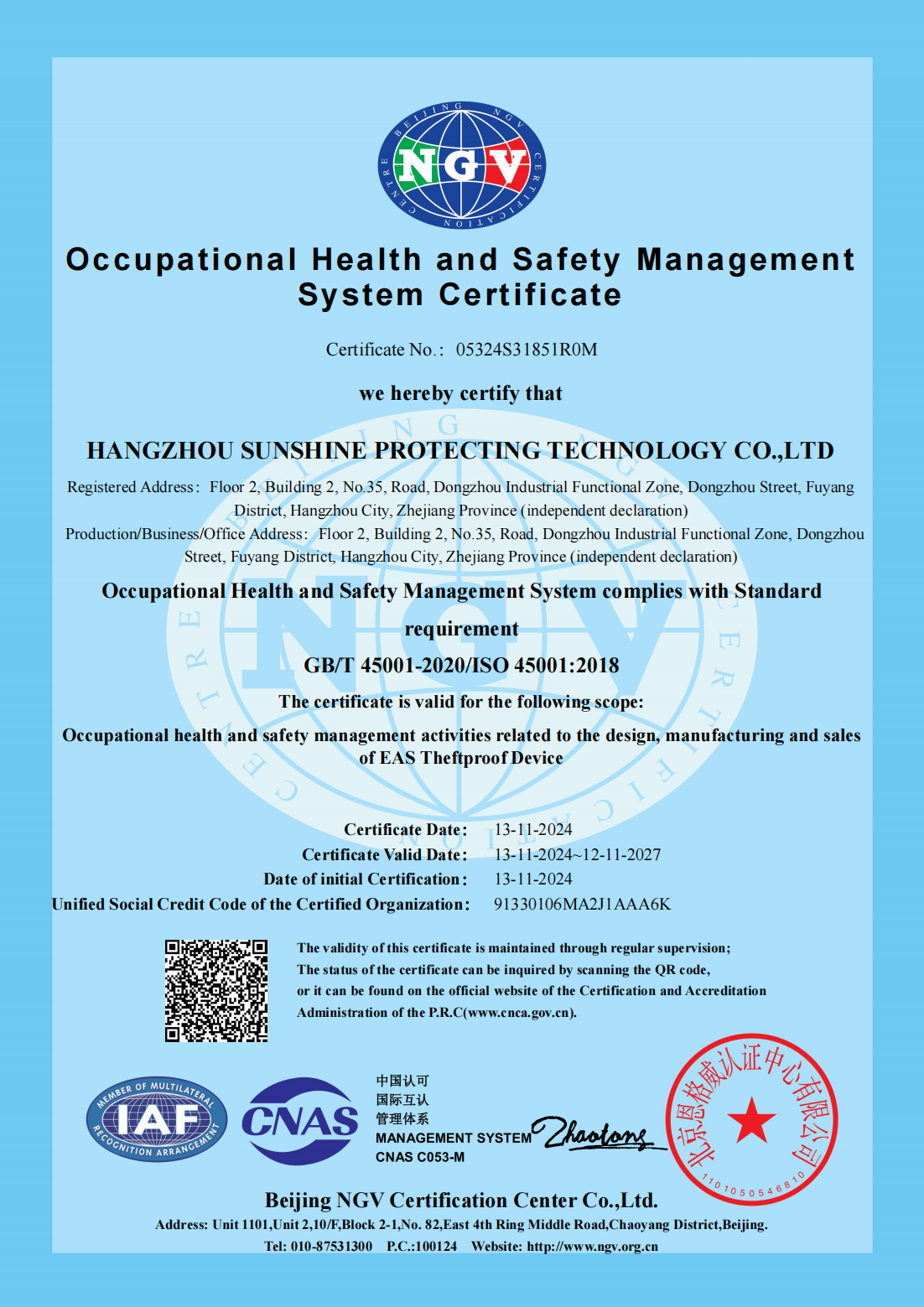

Automation Workshop Established and ISO 9001 Certified

In 2012, SunPro established an automated production workshop with 40 fully automatic winding machines to expand capacity and balance product supply and demand. This initiative, aligned with the government’s “Automation Instead of Manual Labor” policy, increased monthly output by 30 million units. In the same year, the company obtained ISO 9001 certification.

Patented AM Magnetizing Machine Developed and Production Capacity Expanded

In 2013, SunPro successfully developed and patented an AM automatic magnet inserting machine. The company also established five new production workshops in the same year, boosting its monthly production capacity to 40 million units.

Launch of Fully Automated Hard Tag Production

In 2023, SunPro independently developed fully automatic hard tag production equipment, marking the beginning of in-house EAS finished product manufacturing.

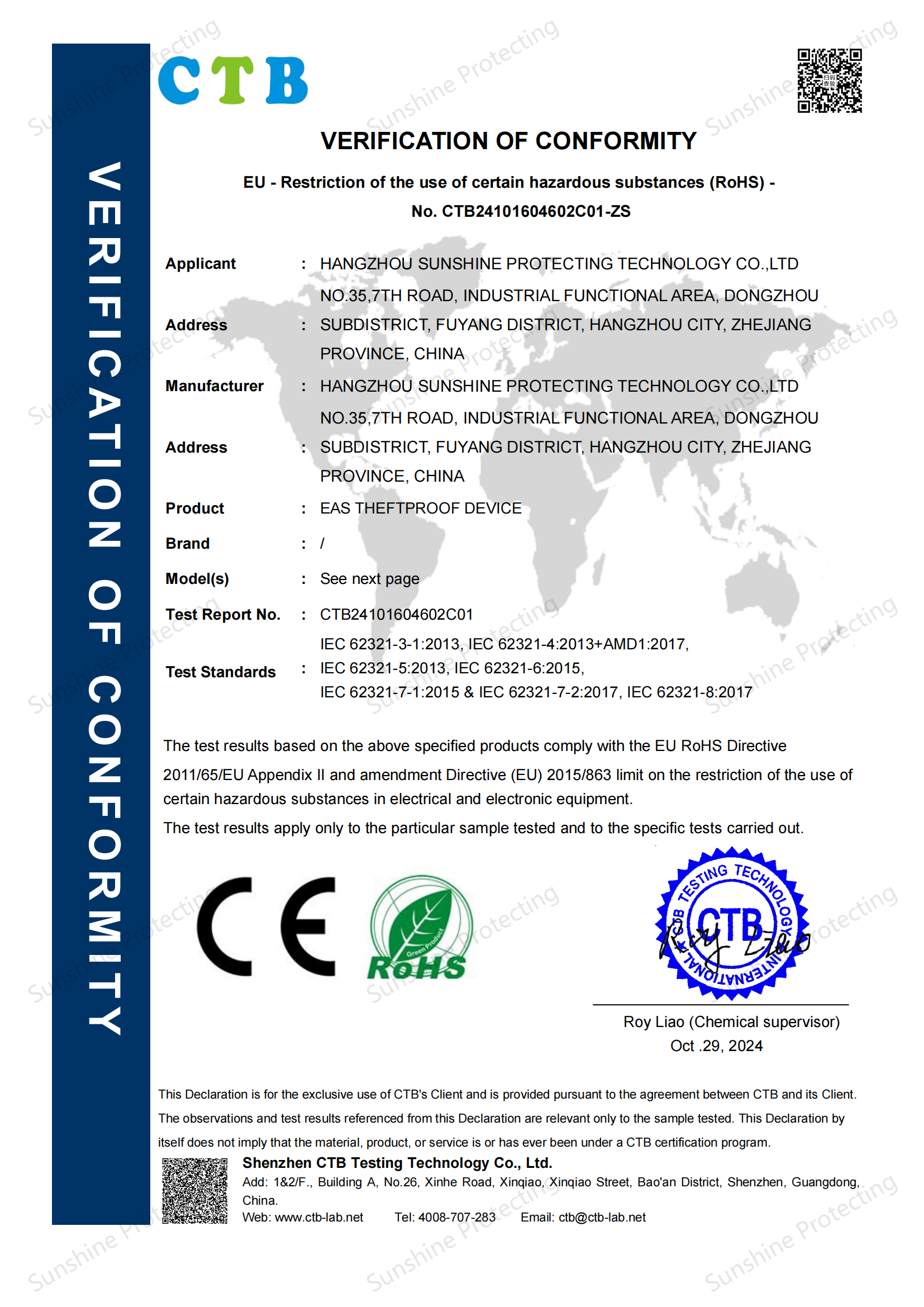

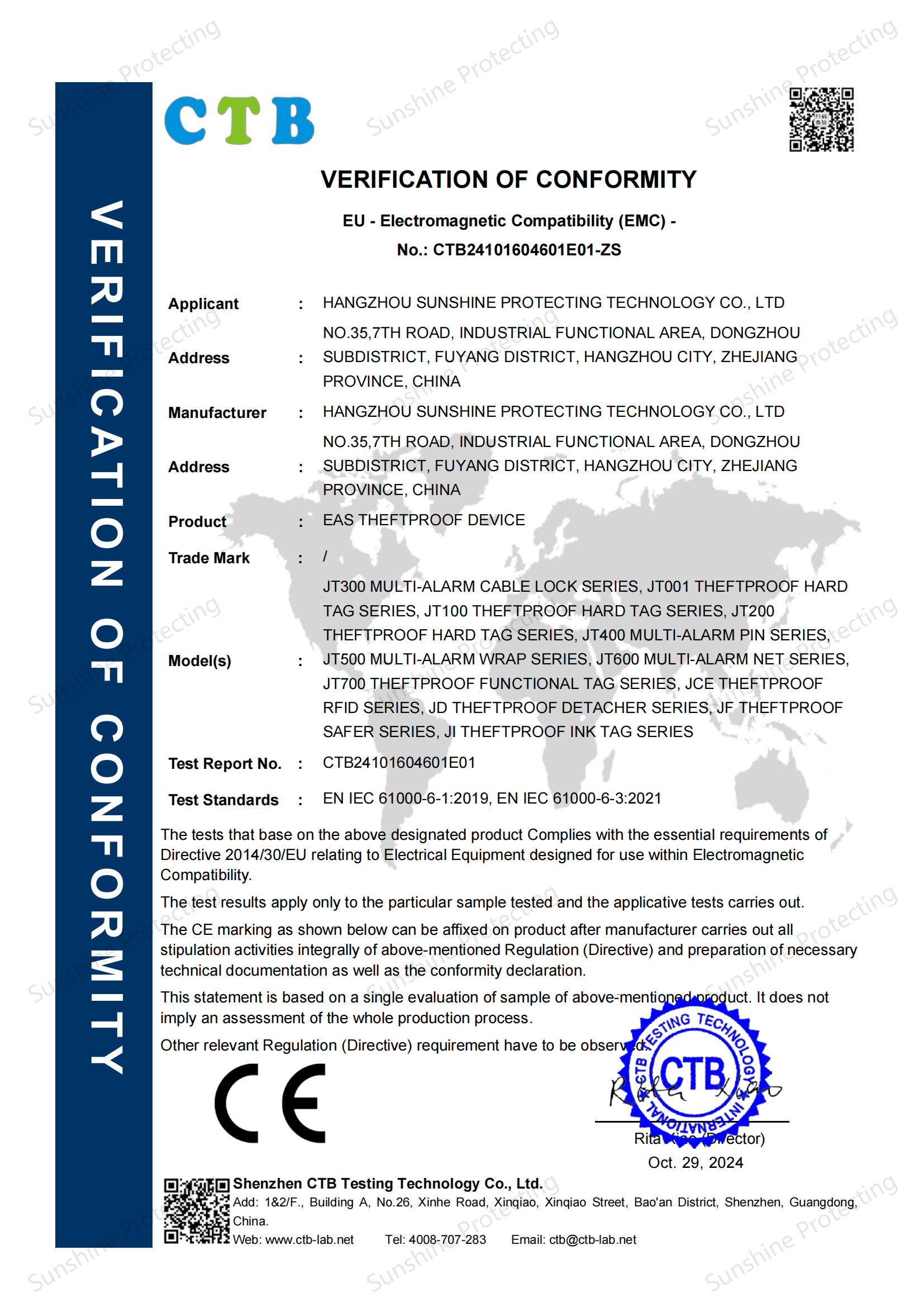

Global Market Expansion and Integrated Development

In 2024, SunPro launched a comprehensive overseas marketing campaign, expanding its global reach to more than 30 countries. The company established a fully integrated model of production, sales, and R&D, while enhancing its product lines and upgrading equipment to meet growing international demand.